Maximising floor space for a live music small bar

Lyric Lane is a bar, café and live music venue built and owned by the Mako Group. The exciting Maylands-based project required a draught beer solution that could work across a multi-level building from one central cool room in order to maximise floor space in the venue.

A brand new fit-out based on a good word

Being able to provide draught beer was particularly important to our client as their venue would be located next door to a microbrewery, and they wanted to be able to attract the same clientele. The project was a brand-new fit out, which meant Barons was involved in the early design phase.

Lyric Lane reached out to Barons in the early conception phase of the bar based on a multitude of recommendations from a hospitality industry social media group.

Long-term planning for the ultimate solution

One year before installing the new systems, Barons conducted a site visit to discuss the way they needed to run lines, how PVC ducting had to go in, how everything had to be laid before the

install could happen.

Once we understood everything the client needed, we began designing the solution ‘the way the brewer intended’ – which means the beer coming out of the tap tastes the same as the beer that

goes into the keg.

There are plenty of benefits to a beer pump system:

- Ability to push the beer further

- More elevation without increasing gas pressure

- Can reduce a gas bill by 80-90%

- No need to use mixed gas or introduce a foreign gas

- Clients can use C02 gas, a natural byproduct of brewing

- Beer can stay fresher and crisper for longer

- Reduced risk of over-carbonating (which leads to frothy pours)

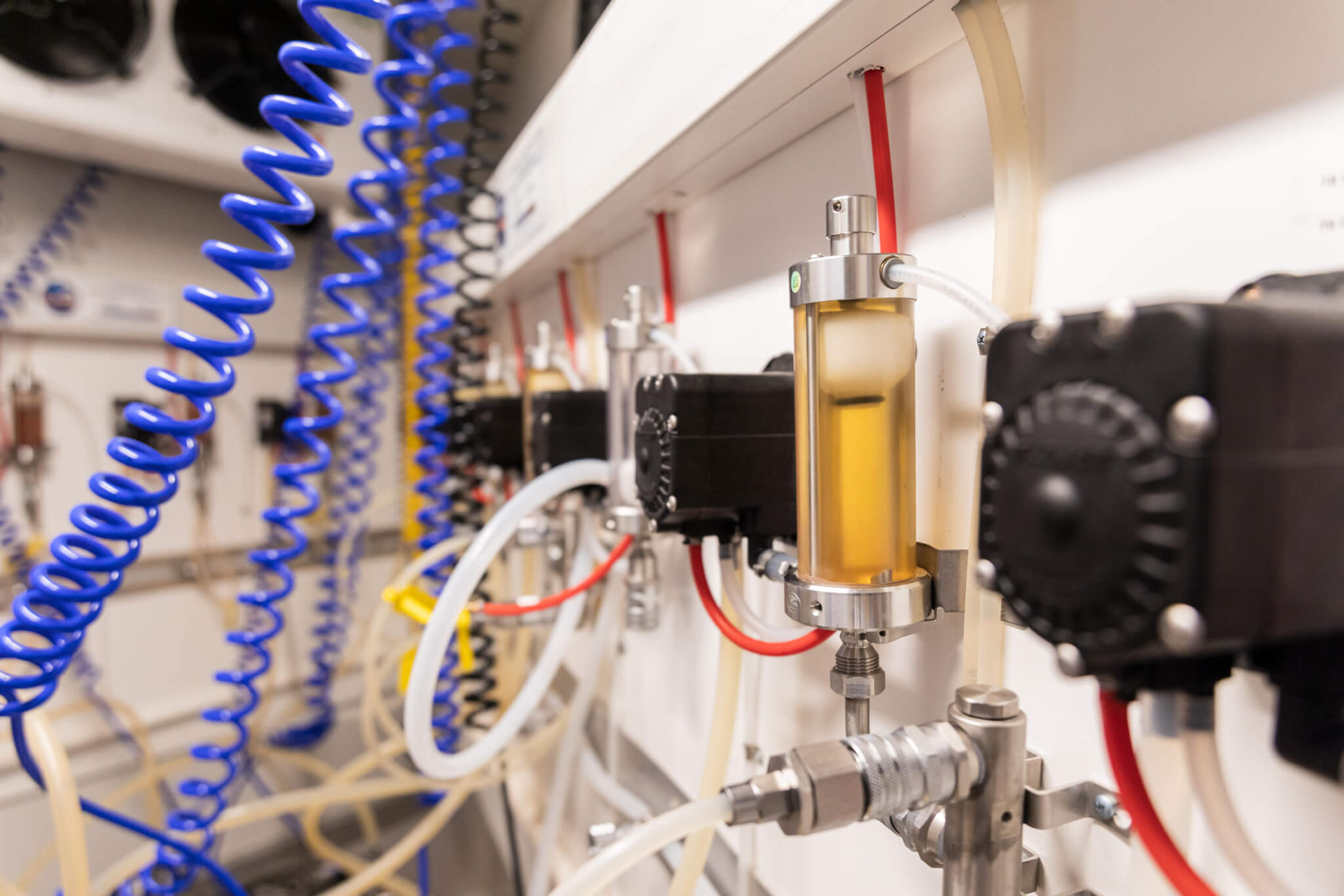

We then designed a chiller plate glycol system for Lyric Lane that would reduce running costs and allow for beer flow across both levels using minimal-sized beer lines. The glycol chiller solution meant the client would be able to chill all the beers across both stations, allowing the owners to add more taps using the same chiller. We also installed chilled water pods, which allow the client to run glass sprayers off the same chiller as the beer system. This system also included many of our standard install items, like Foam On Beer detectors to avoid wastage.

Barons ran beer lines before the ceilings went into place and integrated all activities within the existing build schedule. During the installation phase, we maintained open communication between the builder and developer. We ensured we never inhibited the tradespeople and that we worked their activities into our schedule by running beer lines before the fit-out took place. Once the keg cool room was built we completed the fit-out, ensuring the fridge lines could be run by another contractor. We had two installation teams – one team at the front-of-house and one behind the scenes. The client (who was also the developer) was very helpful and engaged as they installed ducting and ran gas lines ahead of time. This level of involvement is particularly helpful in minimising downtime and allowing the trades to flow in and out without too much overlap.

However, that’s not to say the job went without its challenges. During the installation of the beer pythons we discovered water inside one of the ducts. As the pipe had cracked and the water table had risen over the winter the duct was filled with water. After some time-critical discussion with the builders, we agreed the duct was to be drained, sealed properly internally and pressure tested before we reinstalled the python. Additionally, after Barons completed their work in the cool room there was an external water main burst which flooded the basement and damaged the cool room insulation. This was a crucial moment for the venue, so we decided to remove all of our equipment and reinstall it after the repairs. Its challenges like these that demonstrate Barons will always get the job done properly and will always pitch in to rectify external delays.

Trading out to cash in

Once we overcame these obstacles and completed the beer system installation Lyric Lane opened for business. The Baron’s solution helped to consolidate the venue’s revenue by ensuring little to no beer wastage. Our beer system meant the client could use gas to remove beer from the lines before commencing the cleaning process – a method we call ‘trading out’. That remaining beer can be sold instead of poured down the drain.

Barons Beverage Services is thrilled to have contributed to the success of another small business, not to mention the continued advancement of small bars and live music venues across Perth.